High-Precision Vibration Isolation and Positioning Solutions

Custom-Made, based on Reluctance Actuation

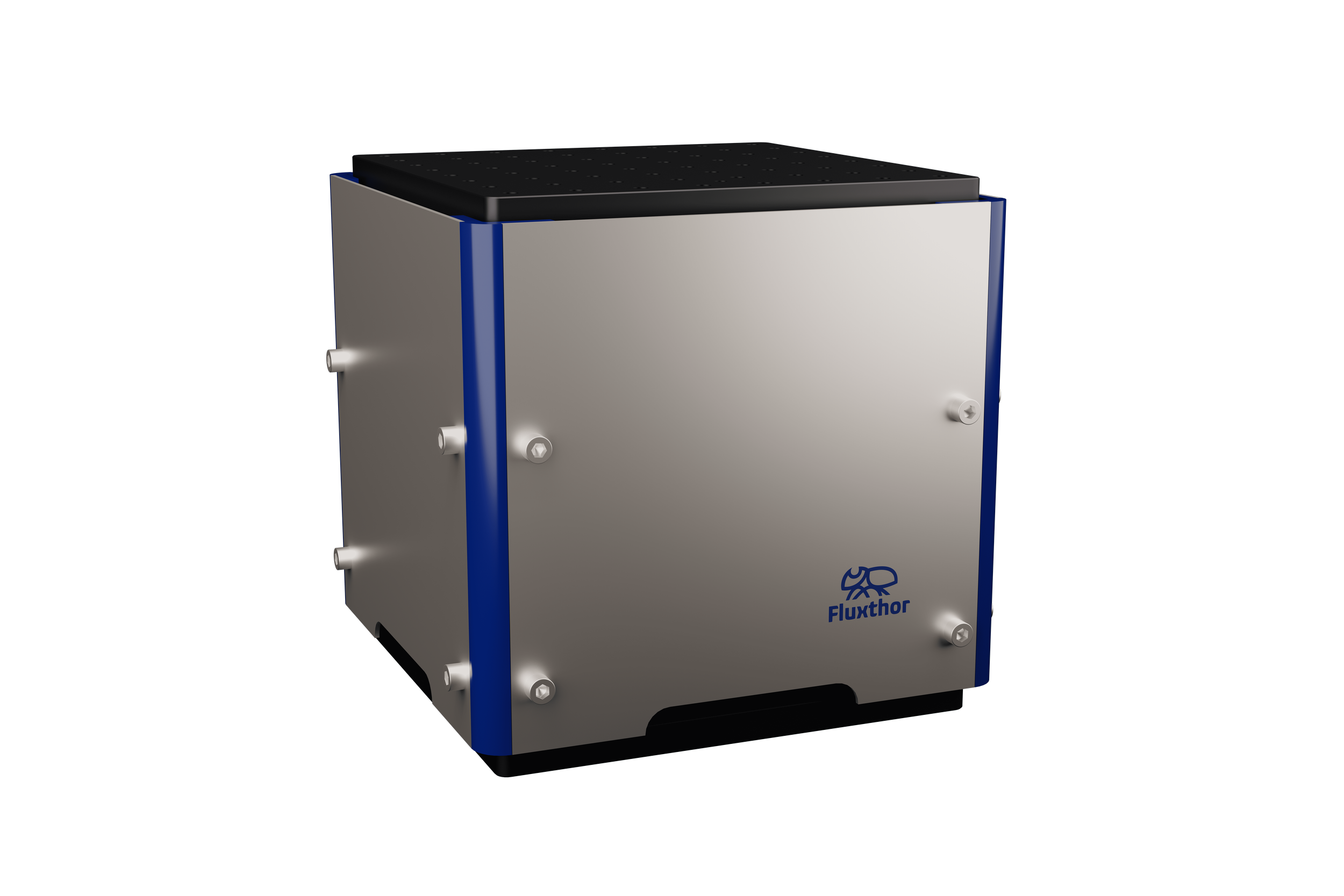

Active Vibration Isolation

By using reluctance actuators in active vibration isolation systems (AVIs), we introduce negative stiffness through magnetic attraction. By creating a combination of positive stiffness of leaf flexures and negative stiffness of the actuator, the resultant will be a quasi-zero stiffness vibration isolation system. By tuning the actuator’s negative stiffness, we can actively control and calibrate the system dynamics according to the specific operating conditions.

The resultant stiffness of the system is the crucial variable on the natural frequency of the system, resulting in the first resonance frequency. By setting this value extremely low, we can suppress vibrations at lower frequencies than any commercially available AVI.

Specification Range

Active vibration isolation starts at

Max suppression (between 2 and 10 Hz)

Active vibration isolation until

Dimensions

Payload

Degrees of freedom

0,1-0,2 Hz

60 dB

100-200 Hz

200x200x200mm

Custom, 5-2000kg

6

Products in Development

Reluctance Actuator

A power full reluctance actuator that can create a highly dynamic motion, dissipating 10x less heat compared to coil based reluctance actuators.

Contactless Magnetic Force Actuation

Coil-free, minimal flux leakage

Vacuum-compatible

Near-zero stiffness achievable

Compact design

Linear Motor

As Reluctance actuators can only move a few millimeters, we are developing a new type of actuator configuration that can use reluctance tuning to displace over a potential infinite displacement range

Motion Controller

Reluctance actuators are hard to control due to their non-linear dynamics. This called us to start developing a in-house controller that can specifically control reluctance actuators in an open-loop

Control & Simulation Software

Understanding and easy of use are critical, we make it easy for all of our customer to configure multi-axis systems and change the control behaviour to match their needs.